What Is A Typical Sign That A Capacitor Is Bad Or Has Failed?

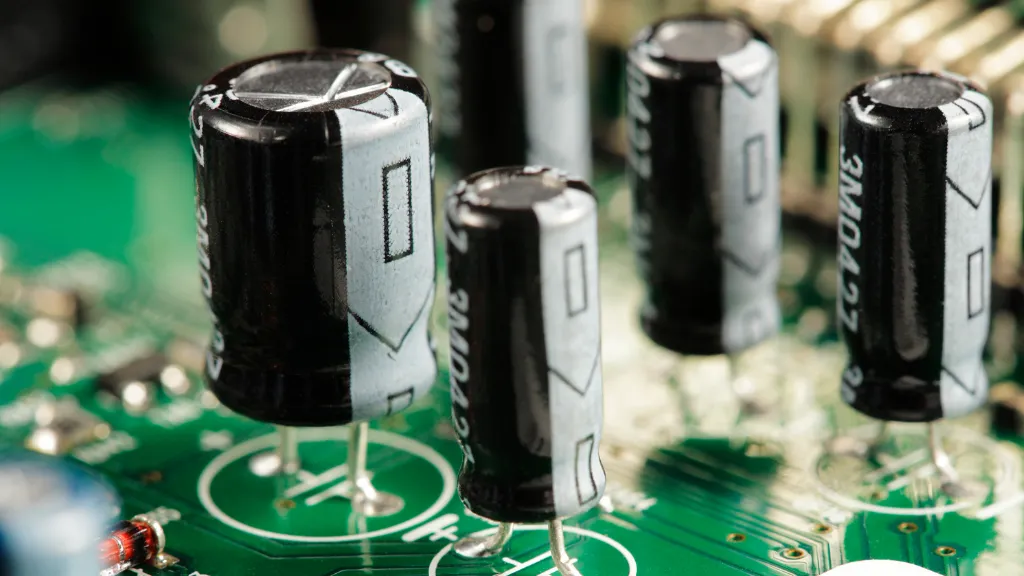

Capacitors are fundamental components in electronic circuits, storing and releasing electrical energy as needed. Their role is crucial in stabilizing voltage and power flow, making their health vital for the proper functioning of electronic devices.

This article delves into how to identify a bad or failed capacitor, a common issue that can lead to malfunctioning or even damage to electronic equipment.

Understanding Capacitor Failure

Capacitor failure is a significant concern in electronics, as these components play a critical role in the functionality and longevity of electronic circuits. Understanding the nuances of capacitor failure is essential for diagnosing issues in electronic devices and implementing effective solutions.

Below, we delve deeper into the common causes, types of capacitors prone to failure, and the impact of such failures on electronic devices.

Common Causes of Capacitor Failure

- Overheating: Capacitors are sensitive to high temperatures, which can accelerate the deterioration of the dielectric material inside them. External factors like ambient temperature or internal factors such as excessive current flow can cause overheating.

- Voltage Surges: Exposure to voltage levels exceeding the capacitor’s rating can lead to the breakdown of the dielectric material, failing. These surges can be sudden and unexpected, often from power spikes or lightning strikes.

- Physical Damage: Mechanical stress, vibration, or impact can physically damage capacitors, leading to internal short circuits or breakage of the connections.

- Aging and Wear: Over time, capacitors naturally degrade. Electrolytic capacitors, in particular, can dry out, losing their ability to store charge effectively.

- Poor Quality or Defective Components: Low-quality capacitors or those with manufacturing defects may fail prematurely under normal operating conditions.

- Incorrect Application: Using a capacitor outside its intended specification, such as in circuits with higher voltage or current than it’s rated for, can lead to rapid failure.

Types of Capacitors Most Prone to Failure

- Electrolytic Capacitors: These are particularly vulnerable due to their liquid electrolyte, which can dry out or leak over time, especially in high-temperature environments.

- Tantalum Capacitors: Known for their high capacity and small size, they can fail catastrophically if exposed to conditions beyond their specifications, such as reverse polarity or overvoltage.

- Ceramic Capacitors: While generally robust, they can crack under mechanical stress or extreme temperature changes, leading to failure.

Impact on Electronic Devices

- Reduced Performance: A failing capacitor can lead to reduced efficiency in power supply circuits, leading to instability in the performance of the electronic device.

- Data Corruption: In digital circuits, capacitors are used for filtering and timing. Their failure can lead to data corruption or erratic behavior.

- Power Failure: Capacitors are crucial for smoothing out voltage fluctuations in power supplies. A failed capacitor can lead to power failures or, in severe cases, damage to the power supply.

- Audio Noise: Audio equipment capacitors are used for signal coupling and noise filtering. Failure can introduce noise or distortions in the audio output.

- Complete Device Failure: In some cases, especially when a capacitor fails short, it can cause a complete breakdown of the electronic device, potentially damaging other components.

Visual Signs of Capacitor Failure

Visually identifying a failing or failed capacitor is a valuable skill in electronics repair and maintenance. Capacitors, when failing, often exhibit distinct physical signs that can be spotted carefully.

Here, we expand on the key visual indicators of capacitor failure.

Bulging or Swollen Top

- Appearance: A bulging or swollen top is the most common and easily identifiable sign of a failing electrolytic capacitor. Normally, the top of these capacitors is flat, but as they fail, the top can dome or bulge outward.

- Causes: This bulging is typically due to gas buildup inside the capacitor. The gas is produced when the electrolyte inside the capacitor begins to break down due to overheating, overvoltage, or age-related wear.

- Implications: A bulging capacitor is a clear sign that it no longer functions correctly and is at risk of leaking or bursting. It should be replaced promptly to prevent further damage to the circuit.

Leakage of Electrolyte

- Identification: Electrolytic capacitors can leak their internal electrolyte when they fail. This leakage can appear as a wet or crusty residue around the base of the capacitor or seeping from the top.

- Consequences: The leaked electrolyte can be corrosive and may damage the circuit board or other components it comes into contact with. It can also create conductive paths on the board, leading to short circuits.

Discoloration or Burn Marks

- Signs: Discoloration, such as darkening of the capacitor casing or nearby circuit board or visible burn marks, are indicators of overheating or electrical stress.

- Underlying Issues: This overheating can be due to internal failure within the capacitor or external factors such as a malfunctioning component in the circuit. It’s a sign that the capacitor has been operating under stress and may have already failed or is close to failing.

Cracked or Broken Casing

- Visual Clues: Physical damage to the capacitor’s casing, such as cracks or splits, is a clear sign of a problem. This can be due to mechanical stress, overheating causing the casing to burst, or manufacturing defects.

- Risks: A damaged casing can expose the internal components of the capacitor to the environment, leading to rapid deterioration and failure.

Rust or Corrosion

- Appearance: Rust or corrosion on the capacitor’s terminals or casing indicates aging or exposure to harsh environmental conditions.

- Effect on Performance: Corrosion can lead to poor electrical connections and reduced performance, eventually leading to failure.

Unusual Size or Shape Changes

- Observation: Any unusual change in the size or shape of a capacitor, other than bulging, such as elongation or shrinkage, can indicate internal chemical or physical changes, signaling a failure.

- Causes: These changes can be due to internal pressure changes, chemical breakdown, or external environmental factors.

Performance Indicators of Capacitor Failure

While visual inspection is a valuable tool in identifying failing capacitors, performance indicators are equally crucial. These indicators often require specific testing methods but can provide a more definitive assessment of a capacitor’s health.

Below, we delve into the key performance indicators of capacitor failure.

Increased ESR (Equivalent Series Resistance)

- Definition and Importance: ESR refers to the internal resistance within the capacitor that impedes the flow of AC. A low ESR is essential for efficient operation, especially in applications like power supplies where capacitors need to charge and discharge rapidly.

- Measuring ESR: Specialized ESR meters are used to measure this parameter. An increase in ESR can significantly affect the performance of the capacitor, leading to issues like overheating and reduced filtering efficiency.

- Symptoms of High ESR: In power supplies, high ESR can lead to poor voltage regulation and increased ripple voltage. In audio circuits, it can cause hum or noise.

Capacitance Drift

- Understanding Capacitance Values: Capacitors are rated for a specific capacitance, which is their ability to store an electrical charge. This value is crucial for the proper functioning of the circuit.

- Measuring Capacitance Drift: A capacitance meter can be used to measure the actual capacitance of a capacitor. A significant deviation from the rated capacitance (often a decrease) is a sign of wear or damage.

- Impact of Drift: Capacitance drift can affect timing circuits, filter circuits, and any application where the specific capacitance value is critical for functionality.

Intermittent Circuit Failures

- Symptoms: Capacitors failing can cause intermittent problems in a circuit, such as sporadic resets in digital devices, flickering screens in monitors, or unpredictable performance in power supplies.

- Diagnosis: These issues can be challenging to diagnose as they may appear randomly and disappear before testing. Observing the circuit’s behavior over time and under different conditions can help pinpoint a failing capacitor.

Voltage and Current Handling Issues

- Voltage Rating: If a capacitor cannot handle the voltage applied to it, it may fail prematurely. This is often due to selecting a capacitor with a voltage rating too close to the operating voltage.

- Current Capacity: Similarly, capacitors have a maximum current capacity. Exceeding this capacity can lead to overheating and failure.

Ripple Current Exceeding Specifications

- Ripple Current: In power supplies, capacitors are subjected to a ripple current, which is the AC component of the current in a predominantly DC circuit.

- Exceeding Limits: If the ripple current exceeds the capacitor’s specifications, it can lead to overheating and a shortened lifespan.

Leakage Current

- Leakage Current Phenomenon: A small amount of leakage current (the current that flows through the capacitor even when it is not charging or discharging) is normal, but an excessive amount indicates a problem.

- Testing for Leakage: This can be tested with a multimeter or specialized equipment and is particularly important in circuits where leakage current can affect performance, such as in timing circuits.

Electrical Testing for Faulty Capacitors

Using a multimeter to test for continuity and capacitance can help identify a faulty capacitor. Please read our guide on How to Test a Capacitor With a Multimeter to learn more.

Conclusion

Identifying a bad or failed capacitor is crucial for maintaining the health and functionality of electronic devices. Recognizing the visual and performance indicators of failure, along with regular testing, can prevent damage and prolong the life of electronic components.

As technology advances, understanding and maintaining these basic components becomes increasingly important.

Author

Alex Klein is an electrical engineer with more than 15 years of expertise. He is the host of the Electro University YouTube channel, which has thousands of subscribers.