What is a Time Delay Fuse

Fuses are known to protect devices and circuits in your home from excess power supply.

However, time delay fuses are peculiar as they have a different working principle than normal fuses.

They are particularly made to allow this overcurrent to go through.

Keep on reading as we explain what exactly time delay fuses are, the working principle of time delay fuses, and the different classes of time delay fuses.

Let’s get right in.

What Is a Time Delay Fuse

A time delay fuse is a fuse that allows overcurrent to run through for a specified period before it blows. Also called a “slow-blow” fuse, these special fuses are typically used in situations where occasional overcurrent is needed to power the protected device, such as in cases of motors.

Time delay fuses perform the same function as any other types of fuses. They simply protect a circuit or equipment from overcurrent or damage from short circuits.

However, different devices have different ways they work and the time delay fuses are particularly used to protect devices that need a certain amount of overcurrent.

Why would a device need overcurrent?

Well, there’s a term called inrush current (also known as input surge or switch-on surge).

This refers to the high and short-term surge of current drawn by certain electrical devices when you attempt to switch them on.

One example of these devices is a motor.

Since a surge or overcurrent is needed for devices like motors to work, the time-delay fuse offers the perfect protection.

The time delay fuse allows this much-needed overcurrent to get through without unnecessarily melting the fuse link.

It allows a current of up to 500% of the regular supply to go through for typically between 10 to 12 seconds.

Working Principle of a Time Delay Fuse

To perform its function, time delay fuses employ certain components and a working principle distinct from regular fuses.

Rather than just using a fuse link that connects to both ends of the fuse and melts immediately, the time delay fuse additionally makes use of a spring, a connector, and a solder with a low melting point.

The spring is attached to the “connector” which has contact with the fuse link to complete the circuit.

The contact between the fuse link and the connector is held down by the low-melting-point solder.

This low-melting-point solder is the main element that delays the fuse-blowing mechanism.

When an occasional current of 100% to 200% of the normal rating passes through the solder for a short time, the solder remains solid and the fuse link remains in contact with the connector.

When overcurrent persists for more than the specified period, heat builds up in the fuse and melts the solder.

Immediately when the solder melts, the spring then pulls the connector away from the fuse link.

This breaks the electrical pathway and interrupts the circuit, hence power supply to the protected device is stopped. This is the working principle of a regular time-delay fuse.

Now, there are dual-element time-delay fuses that have an additional way they operate.

Working Principle of Dual-Element Time Delay Fuses

A dual-element fuse, as its name implies, has two separate components acting together.

These components are the overload element and the short circuit element. The overload element contains the spring, connector, and link that perform the normal principles of slow blow fuses.

When there is a persistent supply of overload current, the solder melts and the spring disjoins the connector from the link.

The short-circuit element, however, helps to extinguish any electrical arc that a high-current overload of more than 200% may generate.

It contains metal fillers in its restricted portions, with these “restricted portions” being holes or “small arclets” within the short-circuit element.

When a short-circuit overcurrent occurs, the metal fillers evaporate and the arclets limit the energy.

The metal fillers then absorb the arc generated during this process, weld back together, and create an insulating barrier that brings the current supply to zero.

You see all these acting within a thousandth of a second.

Classes of Time Delay Fuse

Although there are multiple classes of time delay fuses, three of these are particularly more popular; Class CC fuses, Class J fuses, and Class R fuses

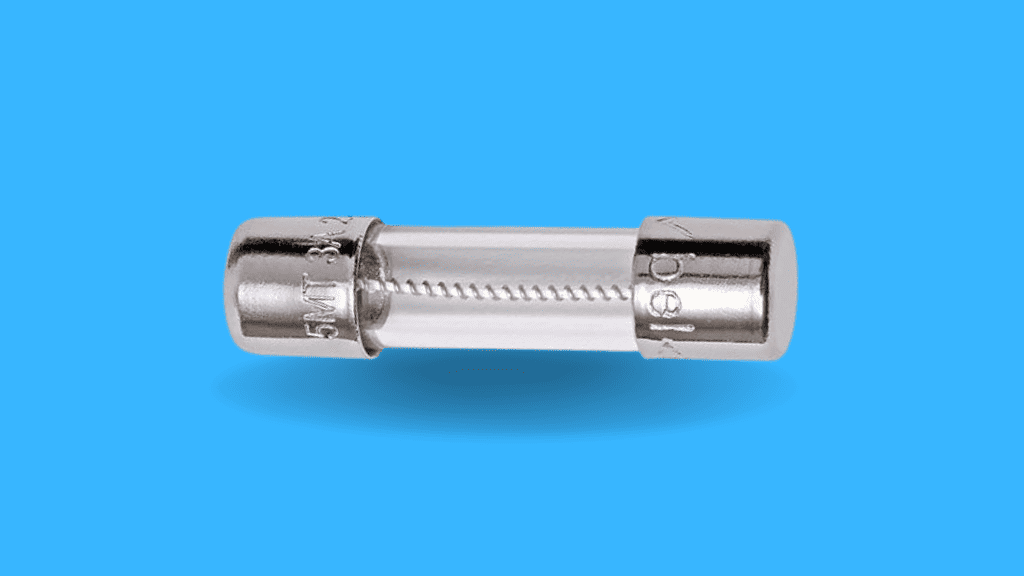

Class CC Time Delay Fuses

Class CC time-delay fuses are rated to hold overcurrent for up to 12 seconds and this overcurrent is allowed to be up to 200% of the normal rating.

These fuses protect components that are more sensitive to overcurrent (such as lighting devices), work with up to 600V, typically have a rating between 0.1Amps to 30 Amps, and have an interrupting capacity of 200kA.

Midget fuses are just like Class CC fuses but work with 250V rather than 600V, and have an interrupting capacity of 100kA rather than 200kA.

These fuses also allow an overcurrent of 200% of the normal rating, delay the fuse blowing for up to 12 seconds, and typically have a rating between 0.1Amps and 30 Amps.

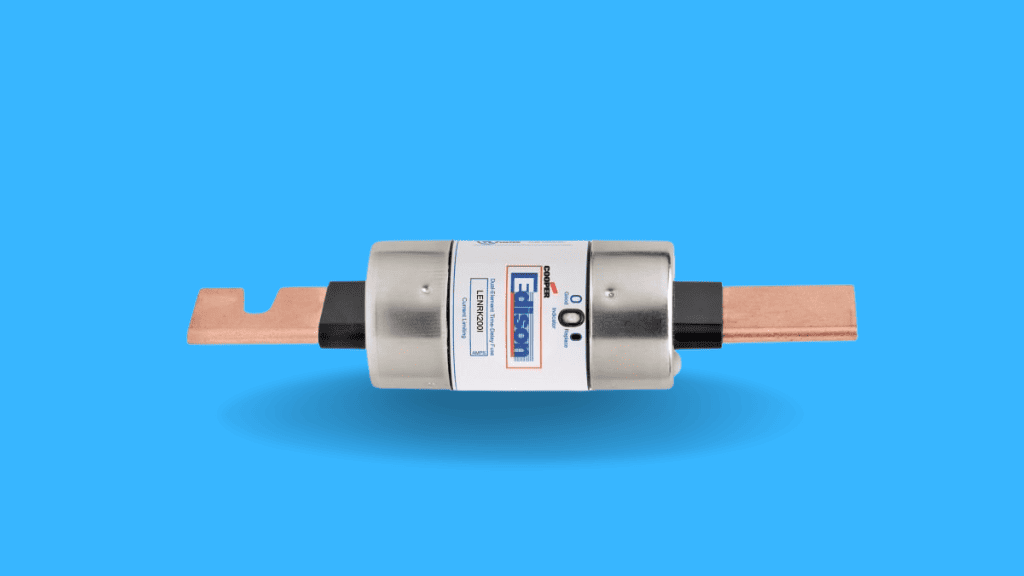

Class J Time Delay Fuses

Class J fuses are also similar to Class CC fuses as they work with 600V and have an interrupting capacity between 200kA.

They however allow overcurrent of up to 500% rather than just 200%, and delay the fuse blowing for an average of 10 seconds rather than 12 seconds.

These Class J fuses are used within electronic motor controllers, drives, soft-starters, circuit breaker back-up, and transformers, among others.

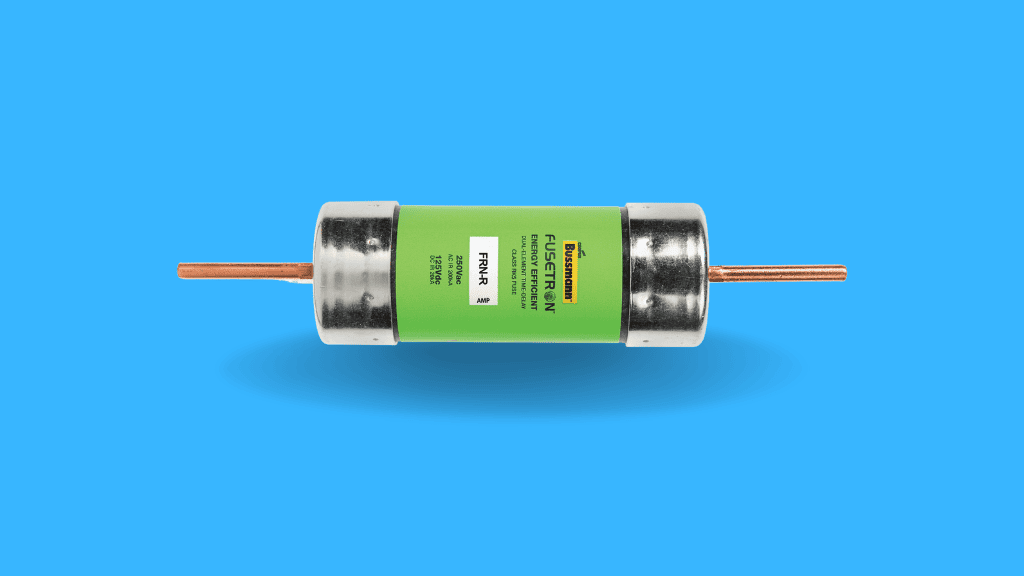

Class R Time Delay Fuses

Class R fuses work just like Class J fuses as they delay for an average of 10 seconds and allow an overcurrent flow of up to 500% of the normal current.

However, these fuses are used within higher-performance environments with ratings between 0.1 to 600 Amps and voltage ratings between 250V and 600V.

Class R fuses have an interrupting capacity of at least 300kA.

There are also two types of Class R fuses, which are the Class Rk1 fuses and the Class Rk5 fuses.

The only difference between these two types of fuses is that the Class Rk1 fuses have a higher limiting power than Class Rk5 fuses, allowing less overcurrent to pass through.

Class R slow blow fuses are used to protect devices that work with high-power inductive loads, such as motors and transformers, and also non-inductive loads, such as lighting and heating devices.

Use Case: How Time-Delay Fuses Help Motors Work

As mentioned earlier, slow blow fuses are typically used in appliances where an inrush current is needed for them to work.

These are devices that need a quick surge of overcurrent to power up, and some examples of these devices include motors and fluorescent lamps in your home.

To get started, motors utilize magnetic fields to create mechanical motion.

However, motors also work with the principle of Lenz’s Law, where the creation of the magnetic field causes an induced voltage called the counter electromotive force or “Back EMF”.

This back EMF is responsible for regulating the energy flowing through the circuit.

Now, the back EMF is directly proportional to the rotation speed of the rotors.

This means the faster the rotation, the greater the back EMF, and the more controlled the current supply is.

However, when the motor is idle (I.e, when the rotors are still), there is no back EMF and there is no control over the energy.

Once the motor is started, there is a surge of uncontrolled electricity supply, which is an overcurrent supply needed for the rotors to start working to create this important back EMF.

The rotors increasingly speed up until they match the voltage supplied to the motor.

In order not to hinder this process, slow blow fuses are implemented.

Normal fuses will blow out and interrupt the electricity supply once this initial overcurrent occurs.

Slow blow fuses, however, allow this initial overcurrent to pass through for some time so that the rotors can start working.

The resultant back EMF then regulates the power in the circuit to the normal circuit rating.

Frequently Asked Questions

What Is the Difference Between a Time Delay Fuse and a Regular Fuse?

Normal fuses blow out immediately after there is an overcurrent supply while time delay fuses allow this overcurrent supply to persist for between 10 to 12 seconds before blowing out.

Can I Replace a Normal Fuse With a Time Delay Fuse?

It is advised that you don’t replace normal fuses with a new time delay fuse. Using time-delay fuses as replacement puts your device at risk of damage as it could be very sensitive to overcurrent.

How Do You Know If a Time Delay Fuse Is Blown?

To inspect time delay fuses, you either check for dark marks around the body or, for more accuracy, use a multimeter to check for continuity between both ends of the fuse.

Author

Alex Klein is an electrical engineer with more than 15 years of expertise. He is the host of the Electro University YouTube channel, which has thousands of subscribers.