What is a Laser Diode?

Laser diodes are at the heart of modern technology, revolutionizing numerous fields, from telecommunications to medical science. A laser diode is a semiconductor device that produces coherent radiation (light) in the visible or infrared spectrum when current passes through it.

This article delves into the intricacies of laser diodes, exploring their workings, applications, and the future of this pivotal technology.

The Science Behind Laser Diodes

Basic Principles of Lasers

Lasers work on a principle called “Light Amplification by Stimulated Emission of Radiation.” It sounds complicated, but here’s the gist: lasers amplify light and produce it in a very focused and coherent form.

This means the light waves are all traveling in sync, which is why laser beams are so sharp and focused.

How Laser Diodes Stand Out

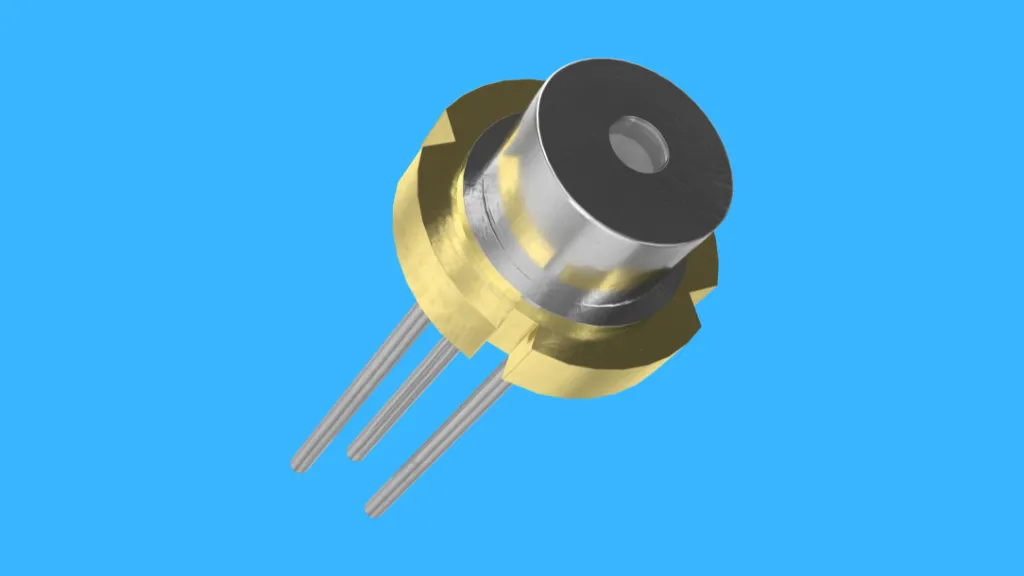

Now, laser diodes are a bit special. Unlike those big, bulky lasers in labs that might use gases or crystals, laser diodes use semiconductor materials (like the stuff in computer chips) to produce light.

This is super cool because it means they can be really small – think of the laser in a DVD player or a barcode scanner.

The Nitty-Gritty: Components of a Laser Diode

- Active Layer: This is where the magic happens. When electricity passes through, it stimulates the material, producing photons (light particles).

- Mirrors/Reflectors: These are on either end of the diode. They bounce the photons back and forth, amplifying them each time they pass through the active layer.

- Semiconductor Material: This is the heart of the diode. Materials like gallium arsenide are common. They’re chosen for their ability to convert electrical energy into light efficiently.

The Process of Light Amplification in Laser Diodes

Here’s a cool part: in the semiconductor, you have electrons and “holes” (basically the absence of an electron). When an electron finds a hole, it combines, releasing energy as a photon.

This process is called recombination. The mirrors amplify these photons; you have a concentrated light beam!

Different Types of Laser Diodes

There’s a variety of laser diodes out there:

- Double Heterostructure Lasers: They are like the standard model great for many applications.

- Quantum Well Lasers: They have a thin layer (or “well”) where the electron-hole recombination happens, allowing for more control over the light produced.

- Quantum Cascade Lasers: They are a bit more complex and used for specific wavelengths, like in spectroscopy.

- VCSELs (Vertical-Cavity Surface-Emitting Lasers): They emit light perpendicular to the surface of the semiconductor, which is great for certain types of optical communication.

Manufacturing and Design of Laser Diodes: A Deeper Dive

A lot is happening behind the scenes regarding manufacturing and designing laser diodes. It’s a field that blends precision engineering, material science, and a bit of what feels like pure magic.

Let me walk you through some of the key aspects.

Materials Used in Laser Diodes

The choice of material is crucial in the design of a laser diode. Typically, we look at semiconductor materials like gallium arsenide (GaAs) or indium phosphide (InP).

These materials are chosen for their ability to convert electrical energy into light efficiently. It’s like picking the right ingredients for a gourmet recipe – the quality and type of material greatly influence the performance of the laser diode.

The Fabrication Process

This is where things get high-tech. Making a laser diode is intricate and requires a clean room environment. It involves several steps:

- Doping: This is where impurities are intentionally introduced to the semiconductor to alter its electrical properties. It’s like adding seasoning to a dish – it must be done precisely and carefully.

- Layering: Various semiconductor layers are deposited onto a substrate. This uses techniques like molecular beam epitaxy (MBE) or metal-organic chemical vapor deposition (MOCVD). Think of it as layering a cake – each layer has to be just right.

- Etching and Processing: The layered material is then etched and processed to create the final structure of the diode. This step is all about precision, as the dimensions and smoothness of the layers play a crucial role in the diode’s performance.

- Testing and Packaging: Once the diodes are formed, they’re tested for performance and packaged. Packaging is not just about protection; it also plays a role in heat dissipation and how the diode will be integrated into a larger system.

Design Considerations

Designing a laser diode is a balancing act. Here are some of the key considerations:

- Efficiency: How well does the diode convert electrical energy into light? This is crucial for battery-powered or heat-sensitive applications.

- Power Output: Depending on the application, you might need a diode that can emit a lot of light (high power) or just a little (low power).

- Wavelength: The color of the laser light is determined by the semiconductor material and the diode’s design. Different applications need different wavelengths.

- Beam Quality: For some applications, like fiber-optic communication, the quality and coherence of the laser beam are paramount.

Challenges in Manufacturing

Manufacturing laser diodes is no walk in the park. Here are some challenges:

- Material Purity: Any impurities can greatly affect the performance of the diode. Achieving and maintaining high purity levels is tough.

- Precision Engineering: The dimensions we’re discussing are in the nanometer range. Achieving this level of precision consistently is a challenge.

- Yield Rates: Due to the precision and purity required, the yield rates (the percentage of good diodes produced) can be challenging to maintain.

- Cost: All of this high-tech manufacturing doesn’t come cheap. Balancing cost while maintaining quality is a constant struggle.

Advancements and Future Trends in Laser Diode Technology

Recent Technological Advancements

- Increased Power Efficiency: One of the most significant advancements in laser diode technology is improved power efficiency. Modern laser diodes can produce more light output while consuming less power, which is a big deal. This means they can be used in more portable applications with crucial battery life.

- Wavelength Diversity: We now see laser diodes that can operate across a wider range of wavelengths. This is super important for applications like fiber-optic communication, where different wavelengths can carry more data over the same cable.

- Miniaturization: Laser diodes are getting smaller and smaller, which is incredible. This miniaturization allows them to be integrated into various devices, from smartphones to tiny medical instruments.

- Beam Quality Improvements: The quality of the laser beam is crucial, especially in applications like cutting or surgery. Recent advancements have led to laser diodes that produce cleaner, more focused beams.

Emerging Applications

- Autonomous Vehicles: Laser diodes play a big role in developing autonomous vehicles. They’re used in LiDAR systems, which help the vehicle “see” its surroundings by bouncing laser beams off objects and measuring the time it takes for the light to return.

- Quantum Computing: This is a really exciting area. Laser diodes are used to manipulate quantum bits, or qubits, in quantum computers. This technology is still in its infancy, but it has the potential to revolutionize computing.

- Medical Diagnostics and Treatment: We’re seeing more innovative uses of laser diodes in medicine, not just in surgery but also in diagnostics and treatment. For example, they’re being used in non-invasive treatments for skin conditions and even in some types of cancer therapy.

Future Directions

- Higher Power Outputs: Researchers are working on developing laser diodes that can emit higher levels of power without compromising the lifespan or efficiency of the device. This would open up new applications in industrial processing and scientific research.

- Integration with Other Technologies: There’s a trend towards integrating laser diodes with other technologies, like micro-electromechanical systems (MEMS) and nanotechnology. This could lead to some really interesting hybrid devices.

- Sustainable and Eco-Friendly Developments: As with many areas of technology, there’s a growing focus on making laser diodes more environmentally friendly regarding the materials used and their energy consumption.

Safety and Regulations: Navigating the Risks of Laser Diodes

When it comes to laser diodes, safety is a big deal. We’re dealing with devices that emit intense beams of light, capable of causing serious damage if not handled correctly. Let’s break down the safety concerns and regulations surrounding these powerful little gadgets.

Safety Concerns with Laser Diodes

- Eye Damage: This is a major one. The focused beam of a laser diode can cause severe eye injuries, even blindness, especially with higher-power lasers. The retina doesn’t have pain receptors, so you might not even realize the damage being done until it’s too late.

- Skin Burns: High-power laser diodes can burn the skin. While not as common as eye injuries, it’s still a risk, especially in industrial settings.

- Accidental Exposure: This can happen in various scenarios, like in a lab or during maintenance work. Even a brief exposure to a high-power laser beam can be harmful.

- Reflections: It’s not just direct exposure. Laser beams can reflect off shiny surfaces, posing an indirect risk.

Regulatory Standards for Laser Diodes

- Classification System: Lasers, including laser diodes, are classified based on their power output and potential for harm. This ranges from Class 1 (safe under all conditions of normal use) to Class 4 (capable of causing damage).

- Manufacturing Standards: There are strict guidelines for manufacturers dictating how laser products should be designed, and labeled, and what safety features they must include, like protective housings and interlocks.

- Workplace Regulations: In settings where laser diodes are used, like labs or manufacturing plants, there are specific safety protocols. These include training, use of protective gear, and proper signage.

- International Standards: Organizations like the International Electrotechnical Commission (IEC) and the American National Standards Institute (ANSI) set global and national standards for laser safety.

Best Practices for Safe Usage

- Training: Anyone using or working around laser diodes should be properly trained. This includes understanding the risks, operating the devices safely, and being aware of emergency procedures.

- Protective Gear: Safety glasses are a must. These aren’t your regular sunglasses; they’re specially designed to protect against specific wavelengths of laser light.

- Controlled Environment: Using laser diodes in a controlled environment where access is restricted and safety measures are in place is crucial.

- Maintenance and Inspections: Regular checks to ensure that safety features are functioning correctly can prevent accidents.

- Emergency Procedures: Knowing what to do in case of an accident, like eye exposure, is vital. A quick response can minimize damage.

Conclusion

Laser diodes are a cornerstone of modern technology, with their applications and importance only set to grow. As we continue to innovate and expand their uses, the impact of laser diodes across various sectors remains a testament to human ingenuity and the relentless pursuit of technological advancement.

Author

Alex Klein is an electrical engineer with more than 15 years of expertise. He is the host of the Electro University YouTube channel, which has thousands of subscribers.