The Role of Fuses in Industrial Electrical Systems

In the intricate web of industrial electrical systems, where power flows relentlessly to drive machinery and equipment, two paramount factors stand at the forefront: safety and efficiency.

Fuses, often overlooked but crucial components, play a pivotal role in maintaining the delicate balance between these imperatives.

This blog delves into the intricate world of industrial fuses, uncovering their significance as guardians of safety and champions of efficiency.

We will explore how fuses safeguard against electrical hazards, prevent costly downtime, and optimize equipment performance. So, let us get started.

The Crucial Role of Fuses

Fuses play an indispensable role in ensuring the safety of personnel and the preservation of critical equipment. This section unveils the pivotal role of fuses as guardians of safety within industrial settings.

Preventing Electrical Hazards

- Electrical Faults and Hazards: Industrial environments are rife with potential electrical hazards, from short circuits to ground faults. Fuses act as vigilant sentinels, swiftly interrupting circuits upon detecting abnormalities, thereby mitigating the risk of electrical accidents.

- Fire Prevention: One of the most critical functions of fuses is their ability to prevent electrical fires. When excessive current flows through a circuit, fuses sacrifice themselves by melting, thereby breaking the circuit and averting potential catastrophic fires.

Personnel Safety

- Protection from Shock: Faulty electrical systems can pose a grave threat to personnel. Fuses, by promptly interrupting dangerous currents, reduce the risk of electric shock, safeguarding the well-being of workers.

- Arc-Flash Mitigation: In the event of a short circuit, fuses play a vital role in mitigating arc flashes, which can cause severe burns and injuries. Their rapid response helps contain and minimize the danger.

Ensuring Equipment Efficiency

In the fast-paced world of industrial operations, efficiency is the lifeblood of success. In this section, we’ll explore how fuses, often overshadowed by other components, play a pivotal role in maintaining and enhancing equipment efficiency within industrial settings.

Consistent Power Supply

- Optimizing Equipment Performance: Industrial machinery requires a stable and consistent power supply for optimal performance. Fuses ensure that power fluctuations and surges are controlled, preventing voltage spikes that can damage equipment.

- Reducing Downtime: Unplanned downtime due to equipment failure can be a costly affair. Fuses act as sentinels, preventing overcurrent situations that could lead to equipment breakdowns and production stoppages.

Cost Savings

- Efficient Energy Consumption: Fuses help maintain a steady flow of power, preventing energy wastage due to irregularities in the electrical system. This not only reduces utility costs but also minimizes the carbon footprint.

- Minimizing Maintenance Costs: Equipment breakdowns are often accompanied by hefty maintenance costs. Fuses, by preventing overcurrent events, extend the lifespan of machinery, reducing the frequency of repairs and associated expenses.

Avoiding Catastrophic Failures

- Protection Against Catastrophic Failures: In high-power industrial environments, catastrophic equipment failures can have far-reaching consequences. Fuses act as the first line of defense, preventing situations that could lead to such catastrophic events.

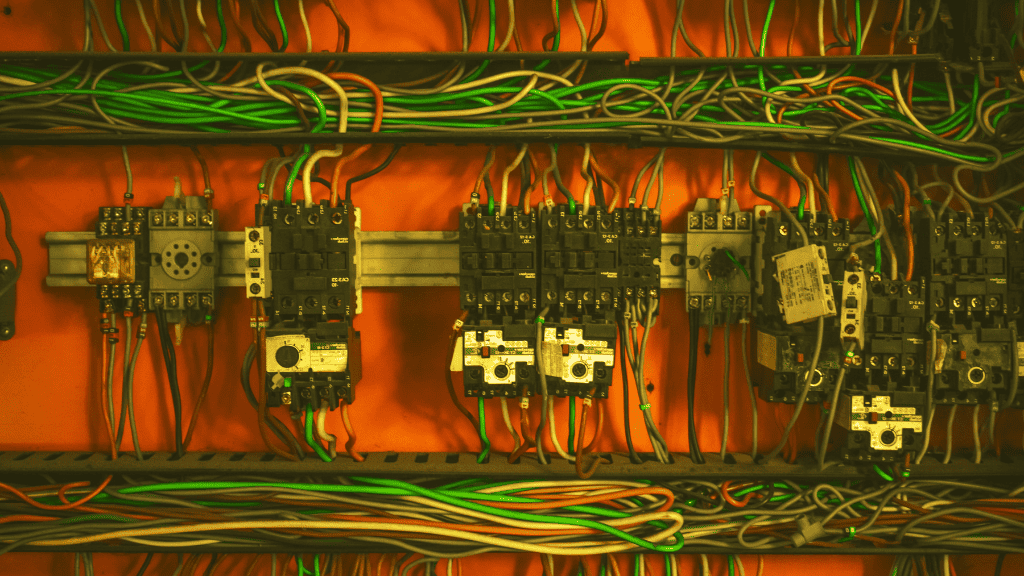

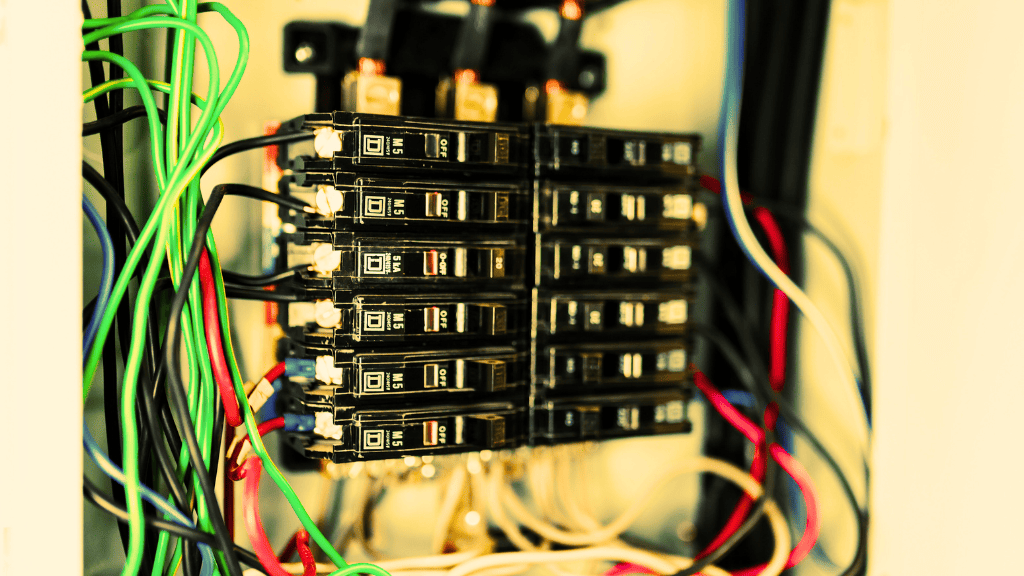

Types of Fuses in Industrial Settings

Understanding the various types of fuses used in industrial settings is essential for ensuring both safety and efficiency. In this section we’ll look into the diverse world of industrial fuses, exploring their characteristics, applications, and advantages..

Semiconductor Fuses

- Overview: Semiconductor fuses are specifically designed for use in semiconductor devices and integrated circuits. They offer precise protection tailored to the needs of these components. For instance, SN74AHCT1G00-Q1 is suitable for automotive power management systems, aiding in efficient energy utilization.

- Applications: These fuses are essential in industries relying on power semiconductors, including manufacturing, energy, and transportation.

High-Voltage Fuses

- Overview: High-voltage fuses are engineered to handle the elevated voltage levels often found in industrial power distribution systems.

- Applications: They are used in electrical substations, power plants, and heavy industrial settings to protect high-voltage equipment from overcurrent conditions.

Low-Voltage Fuses

- Overview: Low-voltage fuses are designed for circuits with lower voltage levels. They come in various sizes and types to suit different applications.

- Applications: These fuses find widespread use in control panels, machinery, and electrical cabinets within industrial facilities.

Blade Fuses and Cartridge Fuses

- Overview: Blade fuses are compact, flat fuses that are commonly used in automotive and industrial applications. Cartridge fuses are cylindrical and come in various sizes.

- Applications: Both types are used in a wide range of industrial equipment and control systems, including HVAC, lighting, and small machinery.

Fuse Sizing and Selection for Optimal Performance

When it comes to industrial electrical systems, choosing the right fuse size and type is critical for ensuring both safety and efficiency. Let’s look into the intricacies of fuse sizing and selection, explore the factors to consider and the best practices to follow.

Calculating the Current Rating

- Load Analysis: Conduct a thorough analysis of the electrical load to calculate the maximum current the circuit may experience.

- Inrush Currents: Account for inrush currents during equipment startup, which may exceed the normal operating current.

Voltage Rating Considerations

- Matching Voltage Ratings: Ensure that the fuse’s voltage rating matches or exceeds the circuit voltage to prevent arcing and potential safety issues.

- DC vs. AC Voltage: Different fuse types may be required for DC and AC voltage applications due to voltage polarity considerations.

Installation and Maintenance Best Practices

Proper installation and ongoing maintenance of fuses are paramount for ensuring safety, reliability, and operational efficiencyThis section will explore the best practices for installing and maintaining fuses in industrial settings.

The Importance of Proper Installation

- Foundation for Safety: Correct installation serves as the foundation for the safety and functionality of fuses. Any errors during installation can compromise the entire electrical system.

- Long-Term Performance: Properly installed fuses are more likely to perform as intended over their lifespan, reducing the risk of unexpected failures.

Inspection and Testing

- Visual Inspection: Regular visual inspections of fuses can identify signs of damage, wear, or overheating. Look for discoloration, cracks, or loose connections.

- Testing Procedures: Implement testing procedures, such as continuity tests, to verify the functionality of fuses in both new installations and during routine maintenance.

Environmental Considerations

- Temperature and Humidity: Monitor and control environmental conditions to prevent extremes in temperature and humidity that could affect fuse performance.

- Corrosion Prevention: Apply corrosion-resistant coatings or materials to fuses in corrosive environments to extend their lifespan.

Advancements in Fuse Technology

Fuse technology itself is far from static. This section delves into the exciting advancements in fuse technology, which are enhancing safety, efficiency, and reliability across various industries.

Traditional Fuses vs. Modern Innovations

- Historical Perspective: Traditional fuses have served well for decades, but their limitations in terms of response time and adaptability are being addressed by modern innovations.

- The Need for Improvement: The surge in technology adoption and the demand for faster, smarter, and more precise protection mechanisms have driven the development of advanced fuse technologies.

Adjustable Fuses for Customized Protection

- Dynamic Protection: Adjustable fuses allow for fine-tuning protection settings, making them adaptable to varying load conditions.

- Energy Efficiency: These fuses minimize unnecessary interruptions by adapting to transient overcurrents, optimizing energy efficiency in industrial systems.

Fast-Acting Semiconductor Fuses

- Semiconductor Technology: Fast-acting semiconductor fuses protect sensitive electronic components in advanced technology applications.

- Precise Protection: They respond rapidly to faults, preventing damage to semiconductors and maintaining the integrity of modern electronics.

Challenges and Solutions

In the dynamic landscape of modern industry, challenges are inevitable. However, with innovation and resilience, these challenges become opportunities for growth and improvement. Lets look into multifaceted challenges faced by industries today and offer insightful solutions to address them.

Technological Advancements and Adaptation

Challenge: Rapid technological advancements demand constant adaptation. Keeping up with the latest technologies and integrating them into existing systems can be daunting.

Solution: Establish a culture of continuous learning and invest in workforce training programs. Collaborate with technology experts to implement scalable solutions that align with long-term business goals..

Environmental Sustainability Pressures

Challenge: Increasing regulatory and consumer pressures require industries to adopt sustainable practices, reducing their environmental footprint.

Solution: Embrace sustainability as a competitive advantage by implementing eco-friendly technologies, reducing waste, and collaborating with industry peers and sustainability experts.

Data Overload and Information Management

Challenge: The influx of data can overwhelm decision-makers, hindering effective data-driven decision-making.

Solution: Invest in data analytics tools and platforms to process and interpret data efficiently. Develop data governance policies and train employees in data management best practices.

Final Words

Fuses, often overlooked in the grand scheme of industrial operations, hold an indispensable role in maintaining safety and efficiency.

As the invisible sentinels against overcurrent events, they silently protect lives and investments, preventing electrical hazards, costly equipment damage, and downtime.

In the intricate web of industrial electrical systems, fuses stand as the first line of defense. They exemplify the principle of prevention, ensuring that power serves progress while maintaining a symphony of safety and efficiency.

These modest components may be hidden from view, but their significance in the electrifying world of industry is resounding and irreplaceable!

Author

Alex Klein is an electrical engineer with more than 15 years of expertise. He is the host of the Electro University YouTube channel, which has thousands of subscribers.