How to Test a Stator with a Multimeter

You are experiencing poor vehicle performance and you just know it is your engine again. All other components seem to be checking out and only the stator remains.

The stator is one of the most important components of your motorcycle or ATV. It is one part of your engine that could be a primary culprit and the cause of all your problems.

But how do you test a motorcycle stator?

This article takes you through all you need to know about testing your stator.

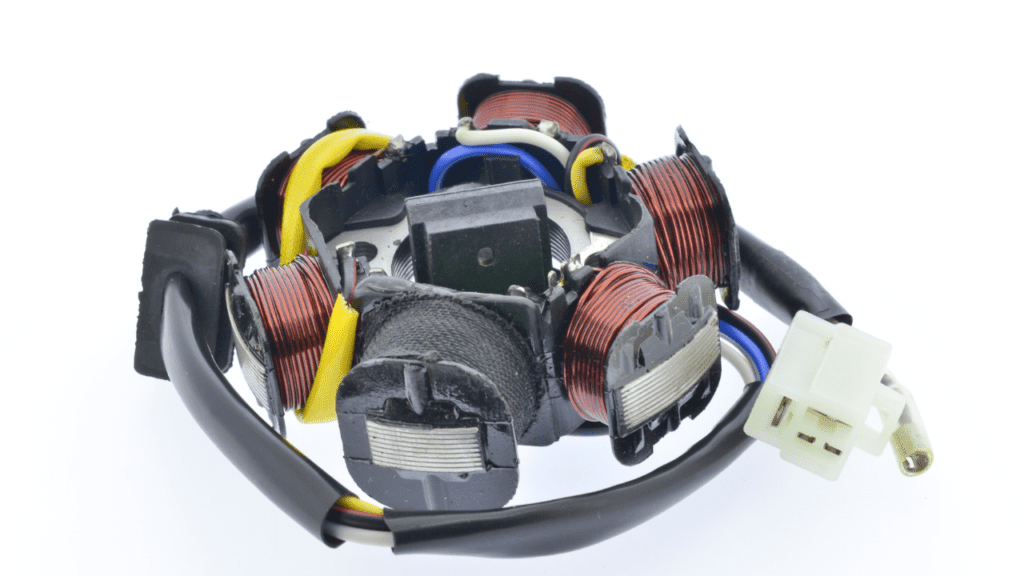

What Is A Stator

A stator is a stationary coil of wires inside the engine case that creates alternating current (AC) voltage which is later converted to direct current (DC) power for use.

Within the stator, a magnet spins and creates AC voltage. AC voltage is then carried out of the case through heavy gauge wires and supplied to the rectifier or regulator at a constant rate.

It is this rectifier/regulator that then converts AC voltage to the Direct Current that powers the whole vehicle.

In motorbikes, the collaboration between stators and rectifiers plays the same role that alternators play in cars.

They regulate the supply of power to the batteries and other components requiring electricity within the bike.

Due to this, when your stator is bad, you’d expect the electrical components within your vehicle to malfunction.

How do you diagnose a bad stator? A multimeter is the only tool you need. It also helps you diagnose other electrical components in your vehicle, so owning one is essential.

How To Test A Stator With A Multimeter

To test a stator, you use a multimeter to either run a static test on the resistance of the wires or a dynamic test on the AC voltage reading from the wires. A static test is run while the engine is switched off, while a dynamic test involves procedures while the engine is on.

These two tests have a lot of procedures and peculiarities with them, so we go into full detail next.

P.S: It is important to note that there are either 3 wire stators or 5 wire stators, and the following steps are in the context of 3 wire stators.

Static Stator Test

The static test is one you undergo with the engine switched off and remains the only option if your engine or vehicle fails to start.

With the static test, you measure the resistance within all the wire phases coming out of your stator. You collectively measure each phase against each other, and also individually measure each phase against a grounded surface.

Let’s name each phase; P1, P2, and P3. Here are the steps to follow.

- Firstly, set your multimeter dial to the Ohm or resistance logo, and you will see that it reads “O.L.” This means that all connections are in an open loop and there is no shortage or grounding with them. If you place the red positive lead on the black negative lead, you notice that the value changes to zero (0), which signifies a bad connection.

- Now, place the positive multimeter lead on one phase and the negative lead on another. For instance, you place the red lead on P1 and the black lead on P2. You also measure between P2 and P3, as well as P3 and P1.

- If the multimeter reads zero “0” while measuring between any of these, there is a problem within your stator or its wires, and something needs to be changed.

Note that the expected ohm reading from this test differs based on the stator model, and not all multimeters are sufficiently featured for this.

The following steps prove to be universal tests you can carry out with every type of multimeter.

You can check each wire individually against a grounded metal surface close by. To do this, you

- Set your multimeter to Ohms or resistance for the “O.L” to pop up on the screen.

- Place the negative black lead on a metal surface close by and place the positive red lead on the phases. Test P1, P2, and P3 individually

- With a good stator, you expect that the multimeter keeps showing “O.L.”

- If the multimeter reads zero or close to zero on any of the phases, that phase has a problem. If it reads zero on all phases, then the solution is changing the whole stator with another stator compatible with your vehicle’s model.

Dynamic Stator Test

The dynamic stator test is carried out when the vehicle is switched on. What is generally measured here is the voltage produced by the stator through each phase.

Note that different stator models have different recommendations for AC voltage readings, so you want to check your manual before proceeding.

To run a dynamic rest on your stator, you

- Set your multimeter dial to AC voltage (VAC) and place the leads into the different stator wire phases. At this point, the engine is switched off and the multimeter should have no reading.

- Switch on your engine and the multimeter should have a positive reading in the 20s.

- Rev up your engine and the reading produced by the multimeter is expected to increase accordingly. If the multimeter does not produce a corresponding increase in voltage reading, then your stator is bad and needs to be changed

This procedure is repeated with the probes interchanged between P1, P2, and P3. If the whole procedures seem tricky, here is a video that shows how to run comprehensive static and dynamic tests and what to expect.

Frequently Asked Questions

How Do I Know If My Stator Is Bad?

Some symptoms of a bad stator include no spark or weak spark supplied to the spark plug, or engine misfiring. You also experience poor performance when you increase RPM and engine backfiring.

How Many Ohms Should A Stator Have?

A good stator is expected to have between 0.2 to 0.5 ohms. This value depends on the model of the stator, so you want to check the manual before coming to a conclusion.

How Do You Test If A Stator Is Working?

To test if a stator is working, you either run static or dynamic tests through the wires. Here, you check for continuity and appropriate voltage readings when the engine is revved up.

What Voltage Should A Stator Put Out?

A good stator is expected to produce a reading above 60 VAC when revved up to 3000 RPM. This value differs based on the stator model, so you have to check your manual to conclude.

How Do You Check AC Voltage On A Stator?

To check AC voltage on a stator, you turn your meter dial to VAC and use the probes to measure the output from each stator wire when the engine is revved up.